Large droplet diameters result in reduced stability and poor extraction efficiencies, because of a low surface/volume ratio. One of the most important factors affecting stability is emulsion diameter. Schematic diagram for the extraction of Cr(VI) using an emulsion liquid membrane (ELM) process.Įmulsion breakage or destabilization results in a decreasing extraction efficiency from the release of entrapped metal. In the third step, the emulsion settling occurs to separate the external aqueous phase finally, a demulsification step takes place to recover the membrane phase (oil) for its subsequent reuse. Although this double emulsion should be stable enough to allow stirring and extraction of the metal into the internal aqueous phase, it should also be easily separated after metal extraction. The second step involves an extraction process, where the final double emulsion (W 1/O/W 2) or ELM is prepared by stirring the W 1/O emulsion on the external wastewater phase to treat (W 2). In the first step, a simple water-in-oil emulsion (W 1/O) is prepared by mixing the membrane phase (oil phase) and the internal aqueous phase (stripping phase W 1). ĮLM processes generally consist of four steps ( Figure 1). The effects of nature and concentration of both emulsifiers on double emulsions properties have been previously discussed. Preparation of a water-in-oil-in-water (W 1/O/W 2) emulsion requires two types of emulsifier: one with a low hydrophilic and lipophilic balance (HLB) for the W 1/O interface, and another with a high HLB for the O/W 2 interface. The major problem regarding the stability of double emulsions is the presence of two interfaces that are thermodynamically unstable. Although this methodology has been successfully applied for chromium removal, but its commercial applications for the removal of heavy metals are limited, due to emulsion instability. Double emulsions have also found applications in separation processes as ELMs.

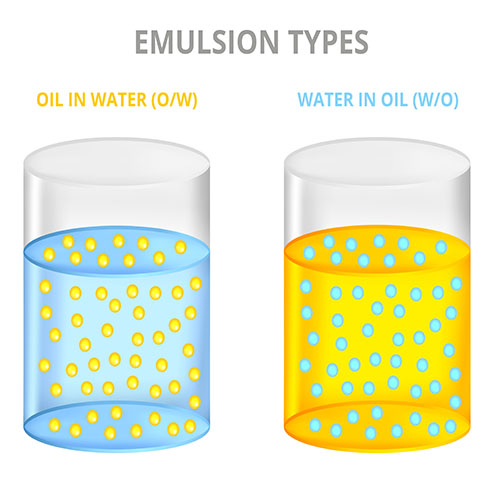

The structural properties of this kind of multiple emulsion lead to a high number of potential applications in medicine, pharmacy, cosmetics, and the food industries. The inner aqueous phase is dispersed into the oil phase as small droplets, while the resulting simple emulsion is dispersed as big drops in the external aqueous phase. Emulsion liquid membranes (ELMs) are really double emulsions, which can be described as emulsions within emulsions.

0 kommentar(er)

0 kommentar(er)